With 35 kilometers of canals Empuriabrava is the largest residential marina in Europe. Born around 25 years ago, the area was especially attractive because it was possible to dock the boat in front of the house and park the car on the opposite facade. But from the very beginning it also suffered a non-stop construction of clonal quaint structures, perhaps because the clients were unaware of the possibilities that another type of architecture could offer.

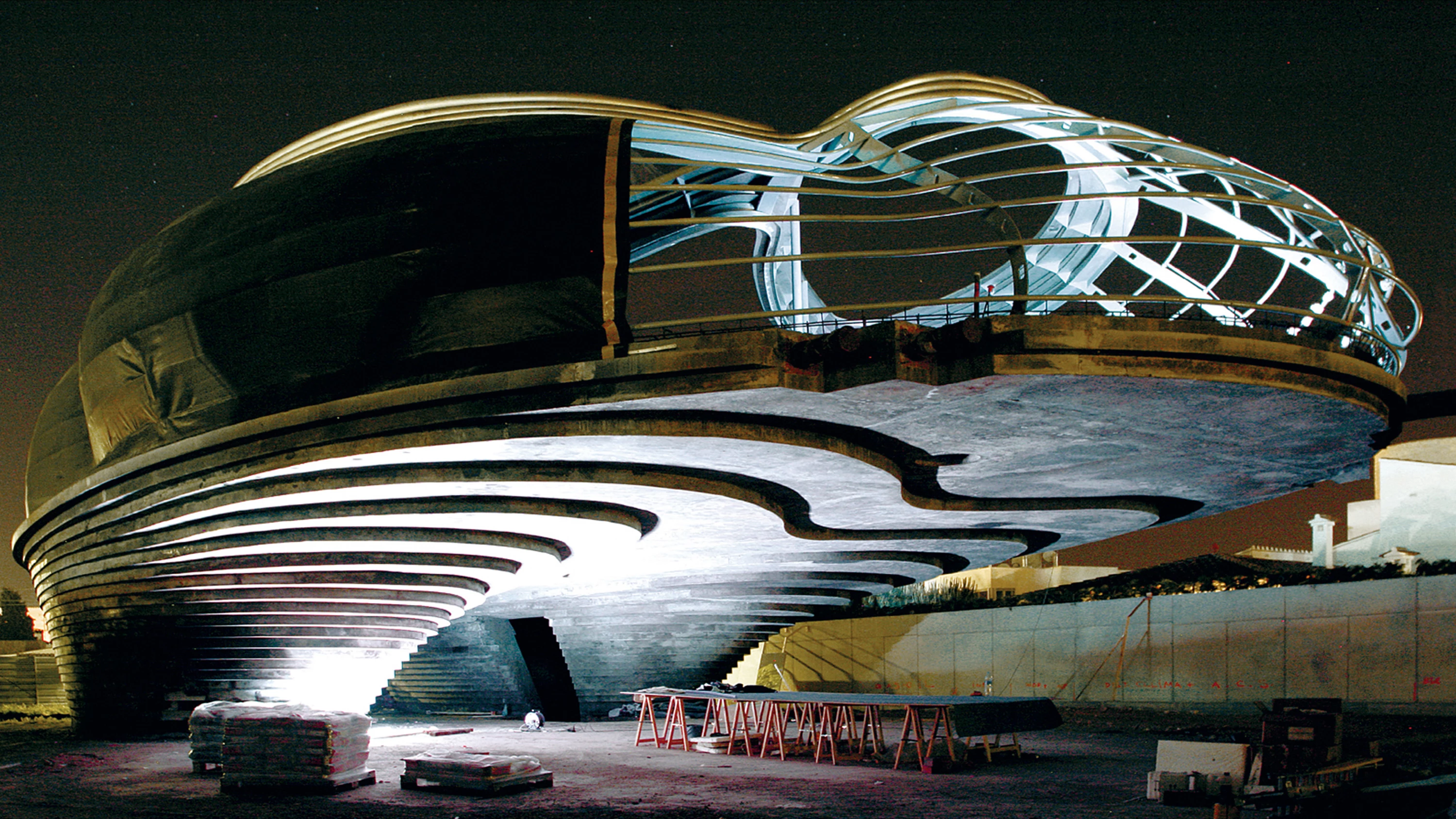

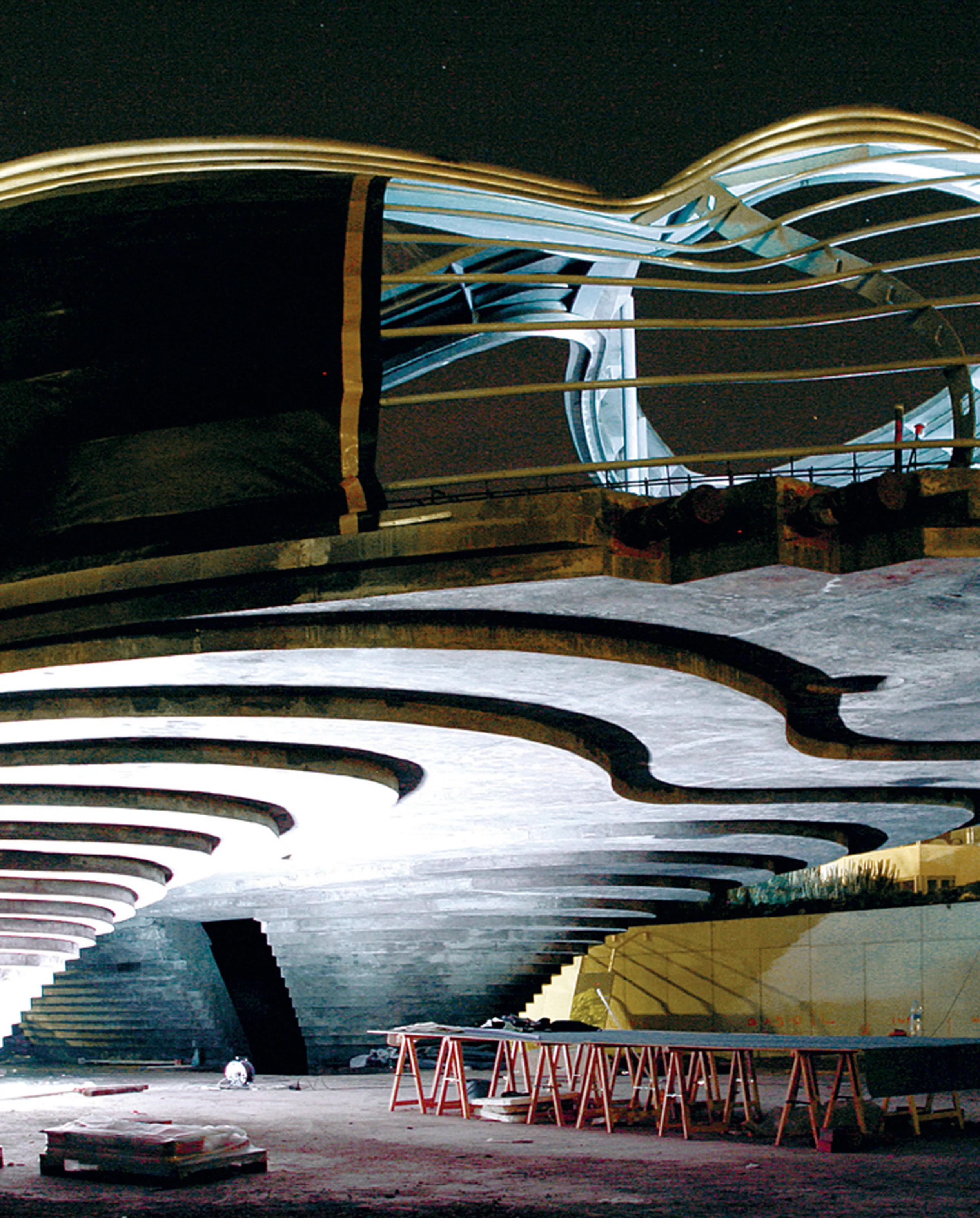

One of the main elements of Empuriabrava is the water, so the design of the house takes a melting ice block as starting point. One of the first moments of its process of decomposition provides an image that becomes the building’s first ‘ultrasound.’ This still photography is scanned and parametrized revealing a threedimensional volume that shows the space it contains. The center is presided by a pool, drawing around it a landscape of pavilions that address the client’s demands.

The house’s complex forms are accomplished thanks to a process called CAD/CAM that transforms a computer model into a real object thanks to the action of a drill. This is how each one of the pieces of the formwork is defined, managing to accurately control its final form.It is designed during long periods of time but is built at an extremely fast pace.

The house is conceived as a hybrid of boat and car. On top of the concrete base there is a steel structure in the form of a chassis wrapped up in a skin designed to control climate, movement, temperature and sound, aside from serving as a support for videos and showings. There are two facades, the north one translucent and the southern one opaque and energy efficient. The former is carried out with an enclosure of milar sheets with kevlar fibers (a polyamide that is five times more resistant than steel and used, among other areas, for boat building), covered with curved pieces of corian, an artificial and malleable stone. The opposite side is covered with EPDM membrane (an elastomer also used in nautics) and on top, resembling scales, it is wrapped up with tiles designed by Toni Camella (author of the mosaics of Santa Caterina) with the collaboration of the artist Frederic Amat. The roof has ETFE cushions and is equipped with a pneumatic mechanism that helps to control the entry of sunlight.

Product of a new digital era, this house has its own web page: www.villanurbs.com...[+][+]

Cliente Client

Familia Gallego

Arquitectos Architects

Enric Ruiz Geli/Cloud9

Colaboradores Collaborators

F. Fassbinder, J. Fernández Río (directores de proyecto proyect leaders); A.Mallol, M. Carreiro, E. Ruffo, R. Duque, A.Macedo, U. Carvalho, H. Young Yu, M. Yebra, M. Durant, A. Pinto ,R. Holl, W. Arbizu, M. Zinnecker, L. Jutgla, M. Soler, M. Kelly-Sweeney, A. Faticanti, S. Bodach, A. Brosel; D. Benito Pó, X. Badia, A. Mallol (aparejadores quantity surveyors)

Consultores Consultants

Boma (estructura structure); PGI (instalaciones mechanical engineer); Estudi Ramon Folch (medioambiente enviroment); F. Amat, T. Cumella (cerámica ceramic); V. Colombet, D. Haim / Galeria Chanim, Cricursa (vidrio glass); Calderería Delgado (estructura metálica steel structure); Covertex (hinchables ETFE ETFE cushions); BEC (cables de acero y fijación cerámica steel cables and ceramic fastening); S. Vila /IFV (piel de corian corian skin); R. Presta (carpintería metálica steel frames)

Contratista Contractor

Obres i Construccions Joan Fustè

Fotos Photos

Lluís Ros