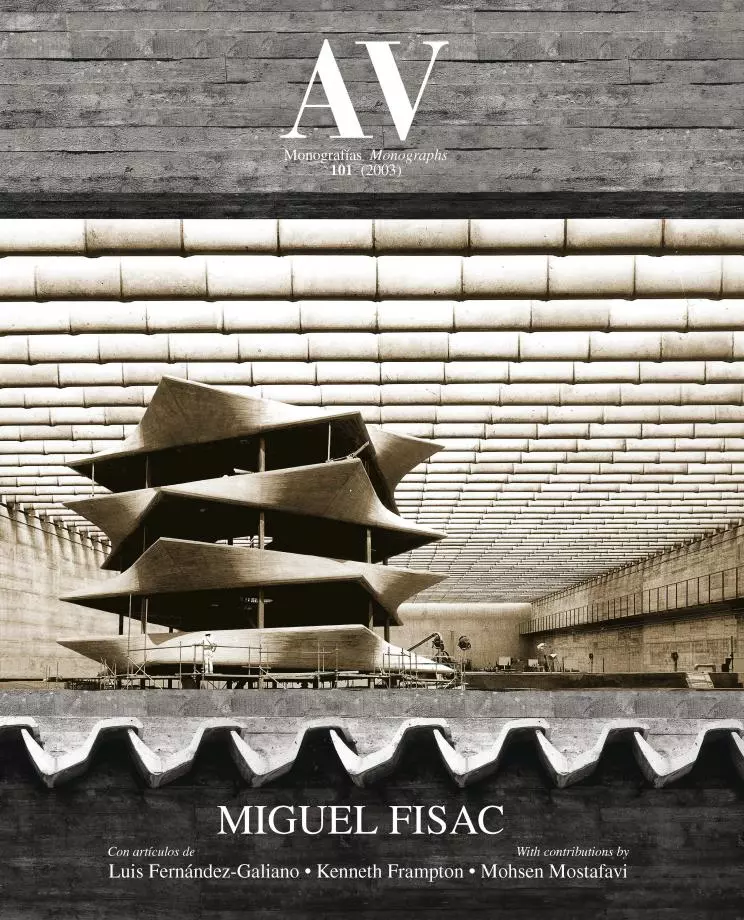

Made Pharmaceutical Laboratories, Madrid

Miguel Fisac- Type Laboratory Prefabrication Health

- Material Concrete

- Date 1960 - 1967

- City Madrid

- Country Spain

The headquarters of Made laboratories, where he already used concrete as single material, foreshadowed two aspects that marked the architect’s production in the sixties decade: on one hand, the fruitful relationship with the pharmacy industry, for which he designed a dozen projects, and on the other, the beams termed ‘bones’ that he used in sheds, schools and houses.

“Here the canopy links a volume of five floors with another of two, as agreed with the local authorities to avoid the three floors allowed. These are solid elements with a changing section to drain rainwater, that falls into a pond. But the most important thing here was how I managed to convince the owner to leave the concrete exposed, by telling him about the Greeks. It so happens that the two moments of architecture that I consider authentic, because they respond to need, are the Greek and Gothic temples. The Gothics had to cover the cathedrals and, as they all collapsed, they invented the pointed arch, then the flying buttress, later on pinnacles to reduce horizontal stress... And the same with the Greeks; the Greek house consisted of four walls and a pitched roof, and they decided that the gods’ houses should be that way too, but much larger. That’s how they built the Parthenon, a building that taught me a lot, because from the propylaea’s center it looks twisted, so that the proportion between its two fronts is a gold number. One must be extremely knowledgeable to place the Acropolis that way. And yet, they covered the marble with stucco. I explained this to the owners of the Made laboratories because in the course of history, it has been particularly hard to assimilate the skin of buildings, and even Ictinus and Calicatres plastered the stone.”

“But the Romans saw the Parthenon without stuccoes and so were able to conceive buildings without them. And when the Renaissance revealed the bare remains from the Roman period, at Pitti palace, Brunelleschi left the stones uncarved. So, it has been a slow process and I did not want to dress the material up, but the client still thought his building would look half finished. Then I had a stroke of luck, because he had bought some patents in Germany, and, when the vendors came he wanted to show them the building. When they saw the almost finished concrete facades, that the client insisted on cladding, the Germans said ‘how modern!, in our country they want to start doing this,’ and, the following day, he resolutely asked me to go ahead with the exposed concrete.”... [+]