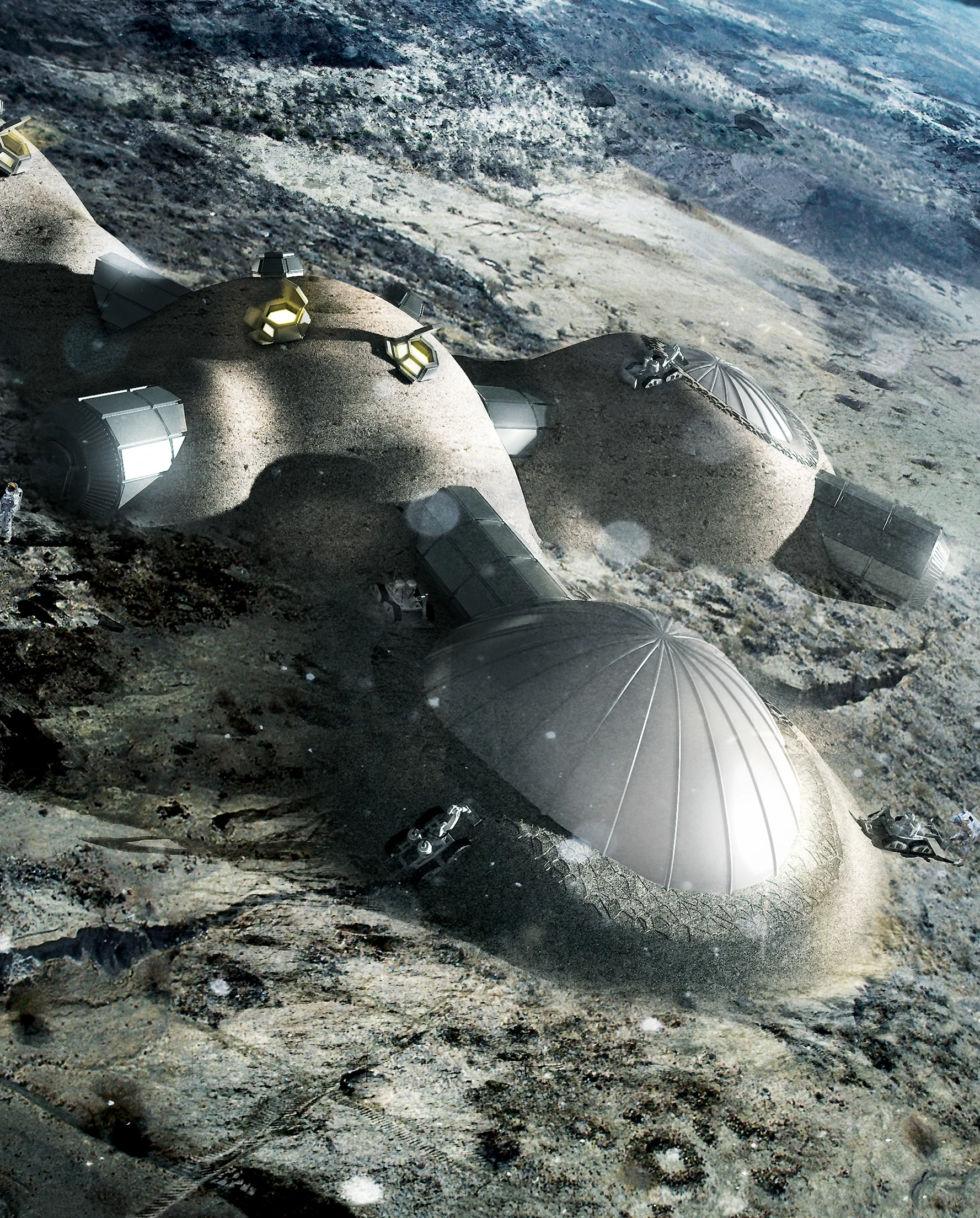

Foster Partners is part of a consortium set up by the European Space Agency (ESA)to explore the possibilities of 3D printing to construct lunar habitations. Addressing the challenges of transporting materials to the moon, the study is investigating the use of lunar soil, known as regolith, as building matter.

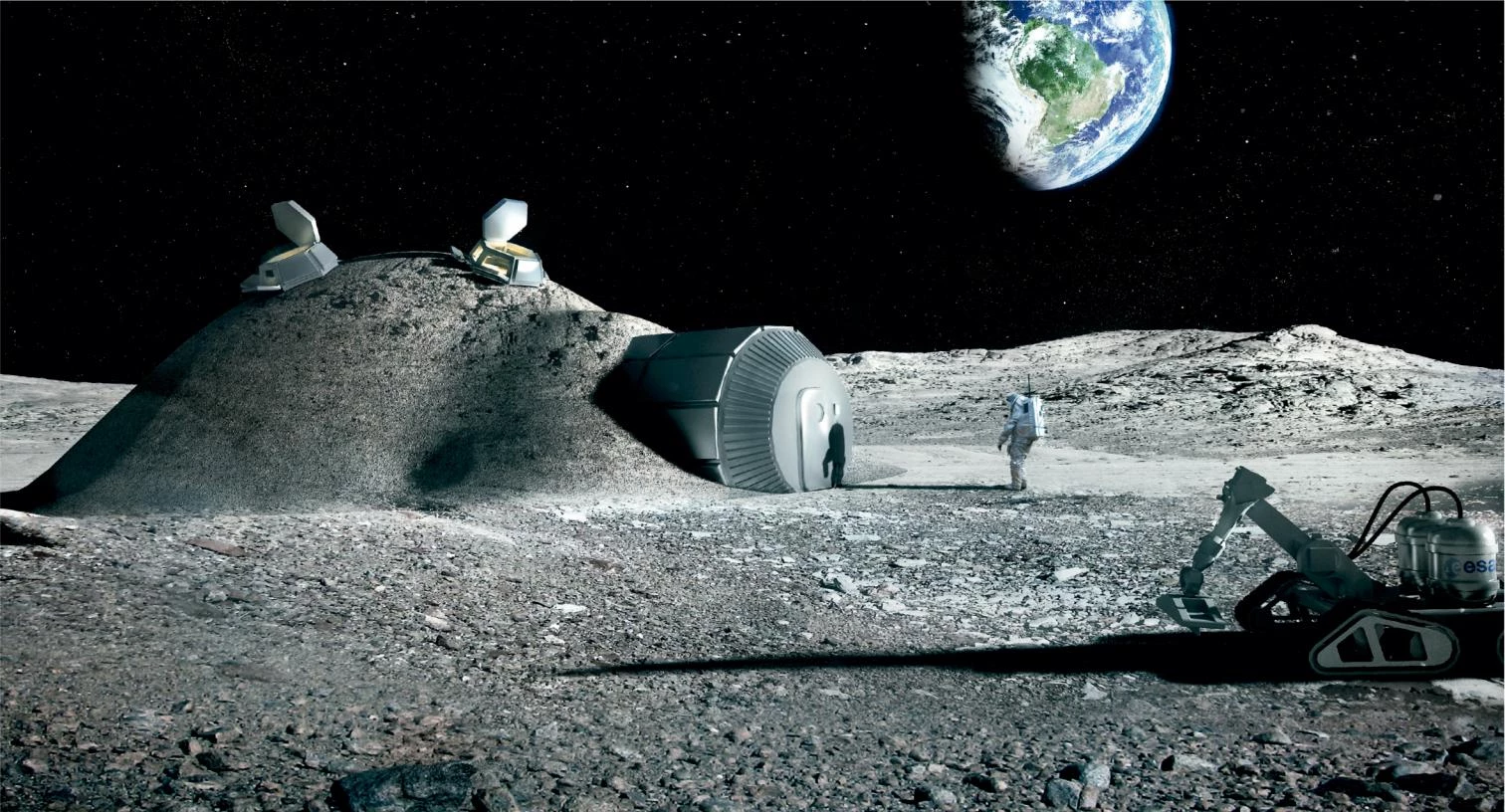

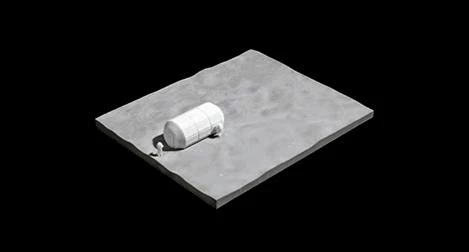

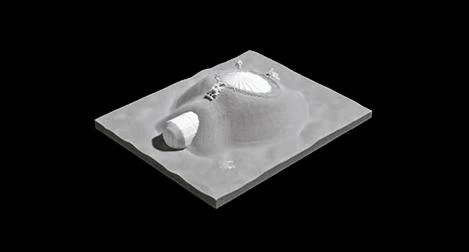

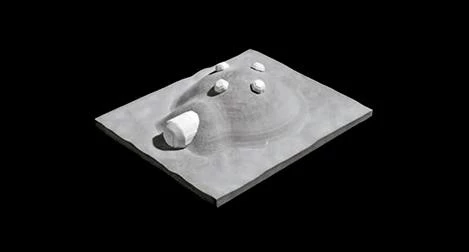

The practice has designed a lunar base to house four people. Devised as a weight-bearing ‘catenary’ dome design, its cellular structure wall can offer protection from meteorites, gamma radiation and high temperature fluctuations, incorporating a pressurised inflatable to shelter astronauts. The base is first unfolded from a tubular module that can be transported by space rocket. An inflatable dome then extends from one end of this cylinder to provide a support structure for construction. Layers of regolith are then built up over the dome by a robot-operated 3D printer to create a protective shell.

To ensure strength while keeping the amount of binding ‘ink’ to a minimum, the shell is made up of a hollow closed cellular structure similar to foam. The geometry of this structure is groundbreaking in demonstrating the potential of 3D printing to create structures that are close to natural biological systems.

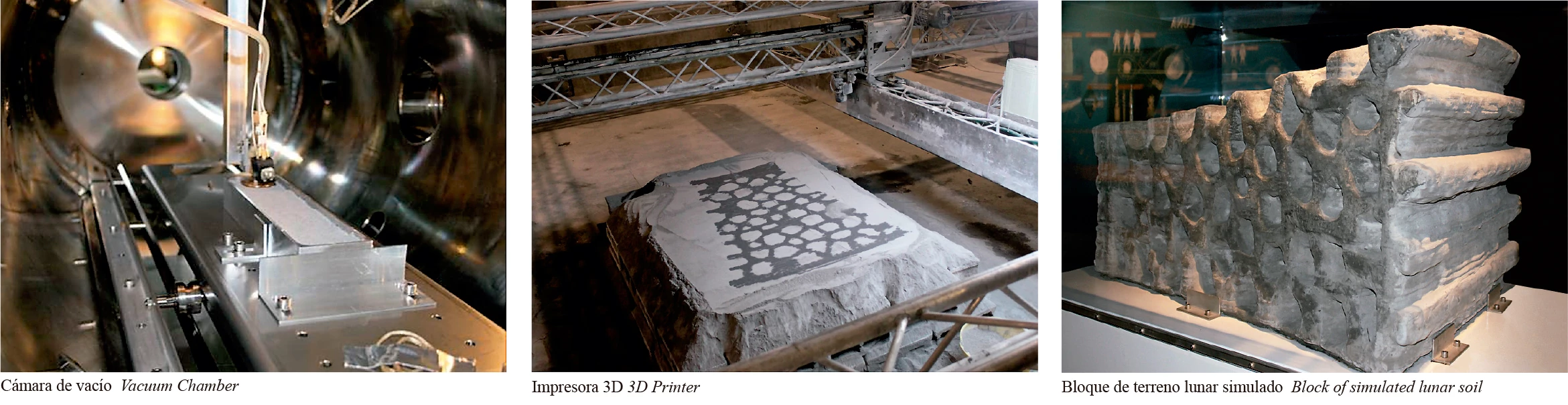

Simulated lunar soil (basaltic rock from a volcano in central Italy, with a 99.8% resemblance to lunar soil) has been used to create a 1.5 tonne mockup and 3D printing tests have been undertaken at a smaller scale in a vacuum chamber to echo lunar conditions. The planned site for the base is at the moon’s southern pole, where there is near perpetual sunlight on the horizon.

3D printing works best at room temperature but over much of the Moon temperatures vary enormously across days and nights lasting two weeks each. For potential settlement, the lunar poles offer the most moderate temperature range. With the foreseen printing speed of 3.5 meters an hour, the building would be completed in one week.

Aside from the European Space Agency, the consortium includes Italian space engineering firm Alta SpA, working with Pisa-based engineering university Scuola Superiore Sant’Anna. Monolite UK supplied the D-Shape™ printer and developed a European source for lunar regolith stimulant, which has been used for printing all samples and demonstrators.

Cliente Client

European Space Agency

Arquitecto Architect

Foster + Partners

Colaboradores Collaborators

Alta Spa —Giovanni Cesaretti— (director del consorcio e ingeniería espacial consortium lead and space engineering); Scuola Superiore Sant’Anna —Valentina Colla— (control de proceso process control); Monolite UK —Enrico Dini— (impresión 3D 3D print technology)

Fotos Photos

ESA; Alta SpA