Maybe it was chance, not the consequence of a premeditated search, but over 3,000 years ago, man found a way to make iron more resistant: by mixing it with carbon. Thus was born the alloy that metallurgical engineering calls steel. The oldest known archaeological remains of this material were found in China, and date back to 1400 AD.

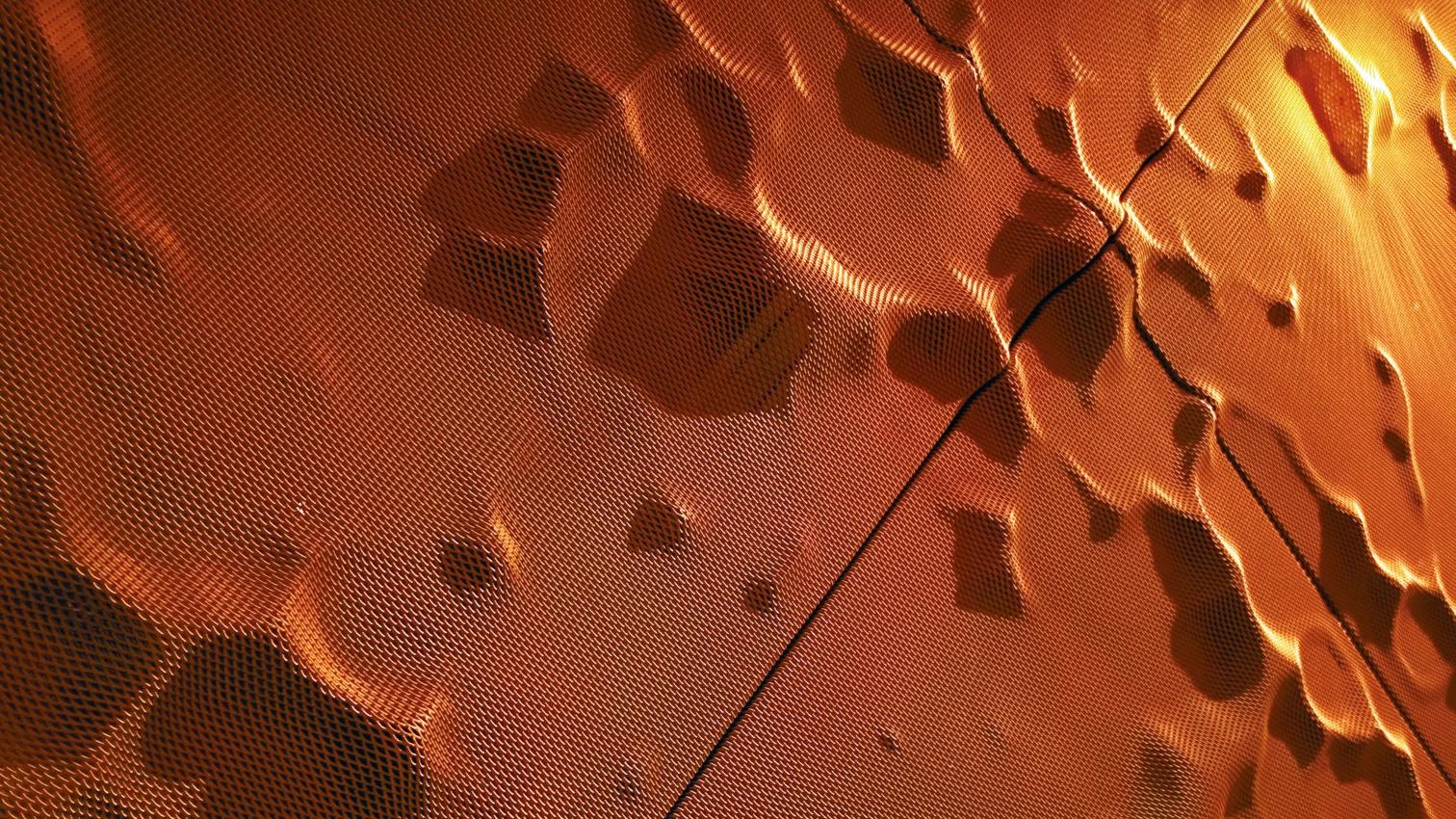

Whether something is iron or steel depends on the amount of carbon in its DNA. The first steels, which are the most common, contain between 0.03% and 1.075% of carbon, and are called ‘carbon steels.’ Today the industry produces a range of special steels in which other elements have been added, metallic and non-metallic alike, which considerably improve the material’s physical-chemical and/or mechanical properties. ‘Silicon steels’ and ‘stainless steels’ are examples. All steel types preserve the metallic characteristics of iron – hardness, tenacity, ductility – and the intrinsic quality of being optimal for fabricating the linear elements of great mechanical resistance that are needed in loadbearing structures: profiles, bars, wires, and cables, as well as superficial elements; plates, sheets, and panels, now available in a variety of textures for the skins of architecture...