Copper, a Contemporary Timeless Material

Versatility and Design

The use of copper dates back to 6000 BC, according to the first evidences of the smelting of this material. There is proof that it was already used as a construction element in Mesopotamia and Ancient Egypt, where ingenious methods were developed using copper staplers of different sizes and shapes to fasten two stones together at the top, giving walls a certain degree of ductility. This system – like the one the Greeks used with other metals, including bronze – served as a joining solution in the structures of the grand buildings of Antiquity, becoming indispensable in earthquake-prone places, such as Karnak in Egypt, not to mention the Parthenon in Athens. Use of copper would extend to other aspects of consruction, mainly for coating roofs and domes, beginning in Ancient Rome, as in Agrippa’s Pantheon.

Nevertheless, it was not until after the first Industrial Revolution that copper took on a more strategic role. The 19th century saw a considerable increase in the use of copper, and it became one of the most used metallurgical resources in the world, along with iron and aluminum. Its use as a system of protection was consolidated in one of the most sensitive points of any building: the roof. Thanks to its versatility, resistance to corrosion, and malleability, copper’s presence in the construction industry much expanded in the 20th century as it became a habitual material not only in joineries, lead roofing, or heating installations, but also in the design of horizontal enclosures and the new curtain wall systems, the cladding of historical ceilings, and structural reinforcements.

Advantages in Construction

Copper is notable mainly for its performance over time, maintaining its technical attributes notably thanks in part to its resistance to corrosion, which remains excellent even in the most adverse conditions. In fact, in very corrosive environments copper can preserve its properties considerably longer than many other metals, which gives it a lot of advantage in decisions on the enclosure of buildings.

One of the most attractive aspects of this material from an architectural point of view is, without a doubt, the wide variation of its color. Starting with natural reddish tones, copper goes through different browns as it ages, eventually taking on the unmistakable green patina characteristic of the oxidation process metals undergo. Copper develops a shallow patina as it comes in contact with the humid environment, the oxygen of the air, and the chemical compounds in the atmosphere, triggering an accumulation of oxygen and sulphur that becomes natural protection of the metal. It is in this process that the color of copper evolves from an initial phase dominated by brown tones to eventually turn nearly black, the point at which it begins to absorb sulphur and chlorine and gradually take on a final green color. Some buildings that benefit from these color phenomena are the City Hall of Gembloux, Belgium, the Helsingkrona Tower in Lund, Sweden, and the Maersk Tower in Copenhagen, Denmark. We can mention the environmental influence of climate zones, and recall how the patina-forming process accelerates in damp atmosphere, as against desert climates, where patination may not even happen.

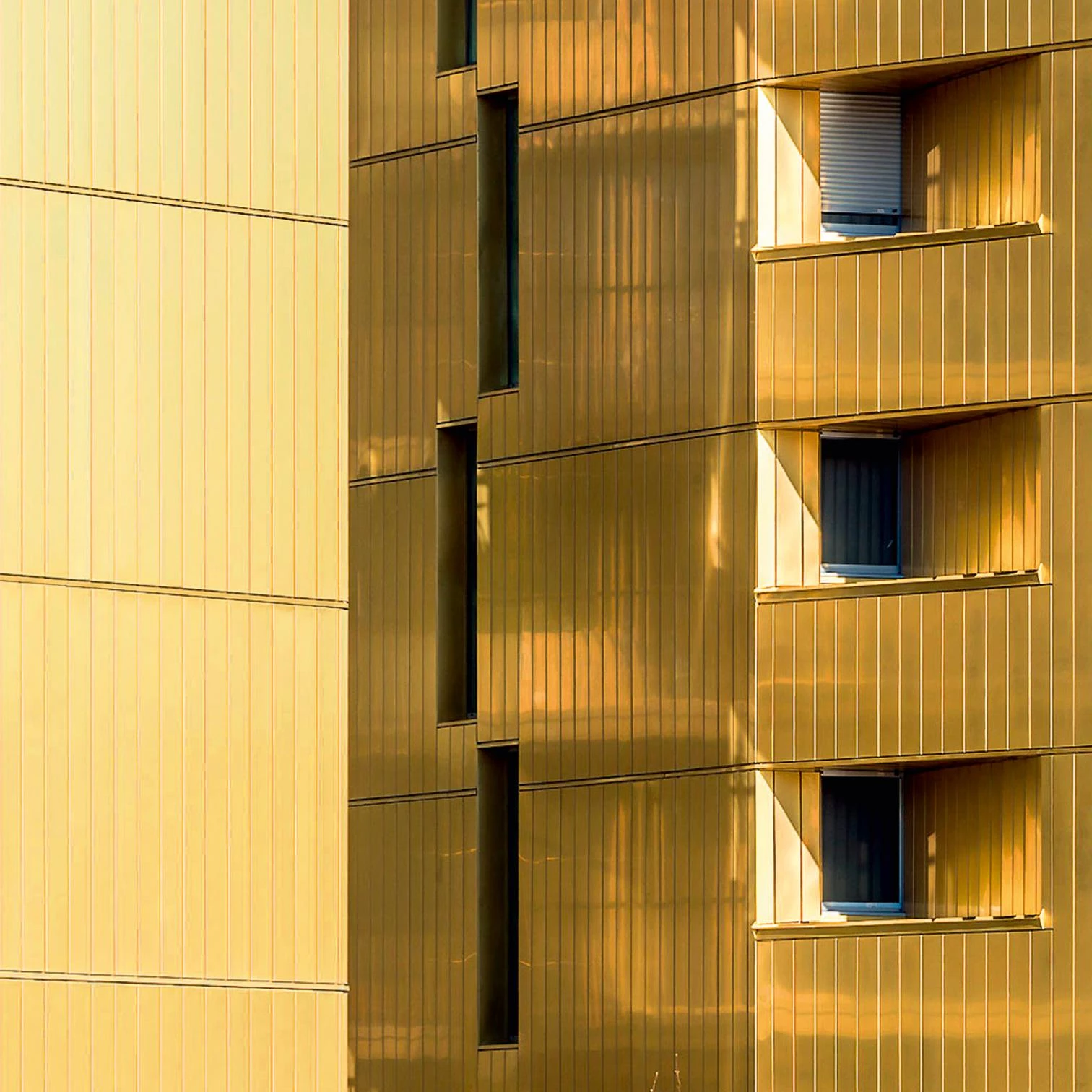

High ductility is another characteristic of copper much appreciated by architects; a ductility that makes the material easy to put in place and join with or fasten to other elements on the construction site, and enables it to lend itself to genuinely innovative forms and designs. Because of its mechanical resistance, copper is able to withstand the pressures required in manipulating it, as when it has to be folded, warped, or heat-sealed, common procedures when working with this material. This is the case in the office building in Hamburg known as ‘the Goldfish,’ a work of Trapez Architektur and the School of Art and 25 flats in Calais designed by ARC.AME, where curved surfaces of impressive quality were obtained. Moreover, the resistance of copper can be increased by means of bent sheets, which comes in handy in certain architectural projects; with this, between two support points the material can get to bear loads of up to 450 kg/m². This solution is applied in buildings like The Moon in Mechelen, Belgium, by Import-Export Architecture, or the apartments at 10 Wylde Street in Sydney, where SJB has in addition created a subtle pattern of perforations on the exterior surfaces, ensuring privacy and solar protection for the dwellings. The new possibilities that perforating copper sheets opens up for us combines perfectly with the most exigent lighting designs, indoors and outdoors. Buildings resorting to solutions of this kind include the King Abdulaziz Center for World Culture in Dhahran, Saudi Arabia, designed by Snøhetta, and the community building in Trondheim, Norway, by HUS Arkitekter. Another important feature of copper is that it is easy to join, by welding, mechanical union, or adhesives.

As for dilation and contraction in response to thermal changes, copper behaves much more stably than metals like lead, zinc, or aluminum. With a dilation coefficient close to 1.67 mm/m for a variation of 100ºC, this material performs much better than other metals in climate zones of drastic changes in temperature. As for watertightness, copper seals liquids off completely, and also performs well in the face of fire in comparison to other materials, with a fusion temperature of around 1085ºC. At the same time, one of the qualities of copper most taken into account when it is chosen as a building material is its extreme lightness. A 1 m², 1–mm-thick sheet weighs only 8930 kg, making copper very manageable on the construction site. Furthermore, copper hardly needs maintenance, which makes it especially good for surfaces that are hard to access or in harmful environments. This puts it in a position similar to that of stainless steel, which is also more resistant than other metals in industrial zones or in places where the atmopshere is much affected by the substantial presence of acids, biological agents, or other pollutants. Finally, with regard to sustainability, copper is very recyclable, almost 100% so, and manufacturing processes involving it are highly efficient in energy terms. This gives it much edge over other metals, such as aluminum and stainless steel, both of which, throughout their production process, have a larger carbon footprint.

Applications and Innovation

The high versatility of copper is evident in numerous examples around the world; a versatility in large measure stimulated by the almost natural synergy with which it interacts with such diverse other materials: wood, brick, stone, glass, etc. Among the most usual applications of copper, the most frequent is as cladding for surfaces of all kinds, including roofs (flat and curved), facades, curtain walls, irregular surfaces… But it also has applications in rainwater drainage systems and interior design, mainly in claddings, frames, and decoration.

At present, the range of solutions carried out with this material has fostered innovation and paved the way for a broad offer of finishes and properties. There are numerous examples of pre-oxidation to be found, such as in the Hydropolis of Wroclaw, Poland, and even of pre-patination, as in the Bus Station of Vitoria, Spain, by Ocenda-Usandizaga Arquitectos. In the same way, it has been possible to slow down the rusting process by means of different types of acrylic lacquer, although here there is a subsequent need for maintenance, of the kind that is unnecessary when copper is left to course its natural cycle.

Also to be kept in mind are the alloys possible with copper, which number almost 400, with all the variations and aesthetic devices that such a selection offers the designer. Cases in point are the copper aluminum used in the Flat Copper building in Paris, by Badia Berger Architectes, and the brass sheets decking the facade of the Kindergarten in Vetroz, Switzerland, by Savioz Fabrizzi Architectes, installed with the double aim of improving resistance to rust and reflecting daylight. All this makes copper a unique metal with infinite possibilities, depending on how it is treated in the factory, how it is ultimately applied, and the environment in which it is applied. Hence, copper-nickel and certain other alloys are highly ductile, highly resistant to corrosion, and high-performing in sea environments, but there are alloys which are ideal in extreme climates, such as copper-beryllium, which boasts high mechanical resistance as well as high resistance to corrosion. But without a doubt the most recognized alloy is bronze, born 4,000 years ago with the marriage of copper and tin, the appearance of which gave rise to the Bronze Age. Since then this metal has come in myriad variations and combinations with other elements, always with the objective of improving its properties, as in the enclosure of the Bosruck Tunnel in Austria or in the City Museum of Chengdu, China.

We have here a highly versatile material in constant development and in possession of excellent technical attributes. Its durability, malleability, and sustainability tell us that it has virtues still to be discovered, that its horizon of applications is near infinite.

E. Ramírez Sánchez is a researcher in the Construction Department of the Madrid School of Architecture.

Buildings of this dossier:

Maesk Tower by C. F. Moller in Copenhaguen

Ferry Teminal by Marge Arkitekter in Stockholm

Six Housing by Guarnier and Mascazzini in Sesto San Giovanni