Polymeric foams can be commercialized in a relatively large number of sectors – from architectural and naval construction to food and packaging, etc. – but without a doubt one of the most important applications of these products is in the building industry, for thermal insulation. Because conventional materials of this kind are made from oil derivatives (energy sources which are non-renewable and have a great impact on the environment) and foaming agents (which contribute to the greenhouse effect), the demand for alternative foams, synthesized from renewable sources, has in recent years increased considerably. One type is synthesized from wheat gluten, a bioproduct derived in the manufacture of ethanol (biofuel), in what is now a very common process.

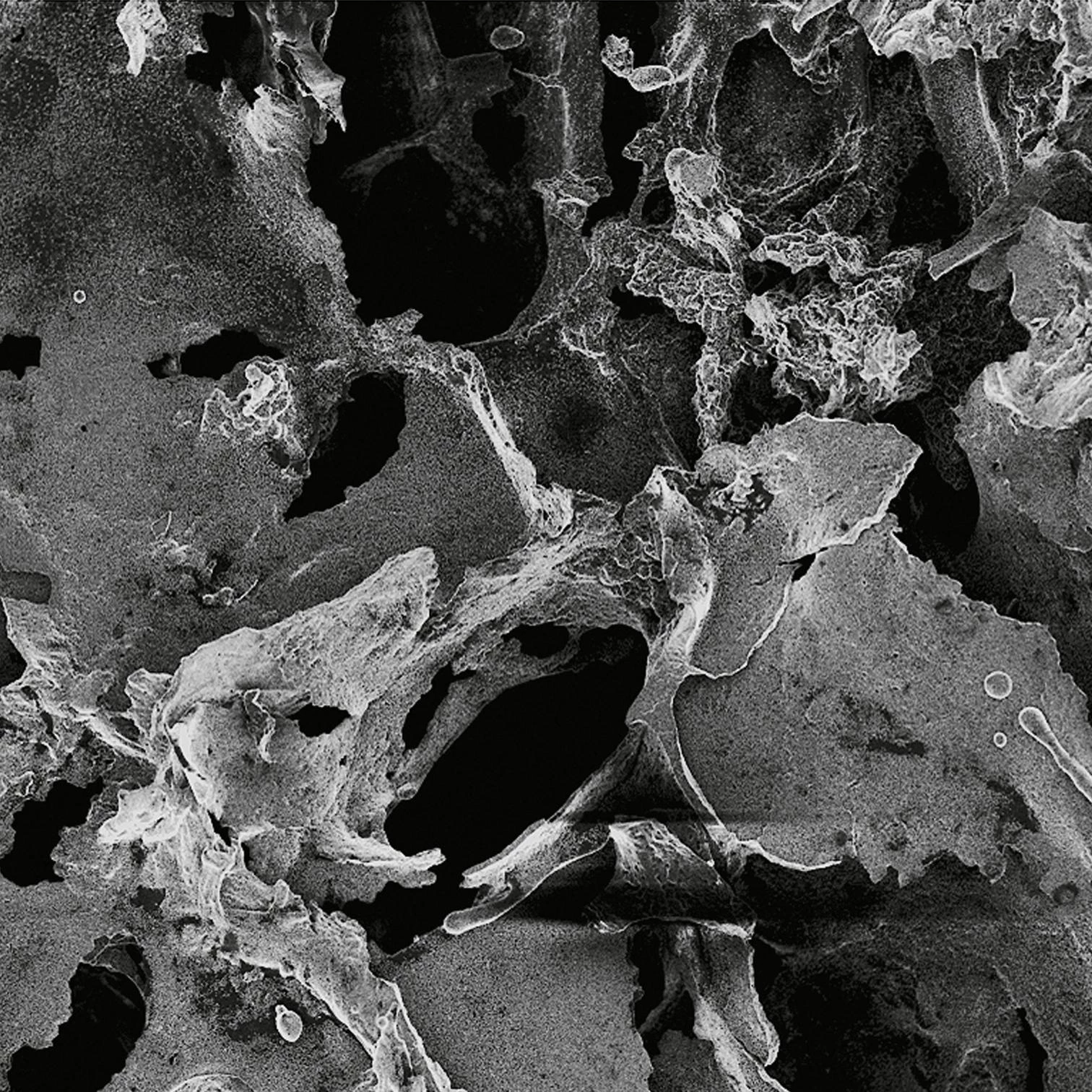

Through the incorporation of an inorganic component, the development of polymeric foams of this kind has the effect of improving the synthesis as well as the properties of the structural network which is built from wheat gluten. For this to happen, different foams synthesized from commercial gluten and silica have been produced as a second phase that is able to react with gluten molecules. The inorganic compound provides additional rigidity as well as longevity for the foams.

It is known that foams which are made exclusively from wheat gluten have very good properties in comparison with other known commercial insulation materials, such as polystyrene or the rigid foam of polyurethane. However, they have no structural stability in water. This means that they dissolve easily. To counter this, a second inorganic phase, silica, has been put into its protein structure. The achievement of this phase of development is to make the silica react to the protein.

One of the principal objectives here is to evaluate the porous structure of these hybrid foams and to see how it affects the composition of the substance, the structure of the protein and, subsequently, the material’s mechanical properties. These hybrid foams have a broad range of densities and are strongly affected by both the gluten/silica concentration used and the temperature that is reached in the process. The range is between 120 kg/m3 and 195 kg/m3 (139 kg/m3 for gluten foams).

As for thermal properties and those for combustion (closely connected to possible architectural applications), the best results so far obtained have been with MTMOS-type (reheated) foams. These are versions that in fact are similar to commercial insulating polymers. In addition, it has been proven that foams perform excellently when burned, and that they can be classified as V-0 materials in accordance with standards.

Hence, it is possible to obtain good polymeric thermal insulants from gluten, one of the proteins that abound in wheat grain, a natural and sustainable source because it can be obtained as a subproduct of already consolidated industrial processes, such as biofuel production. This is an interesting alternative to materials that are ‘dependent’ on petroleum, a source of energy that is as necessary in satisfying current energy needs as it is harmful to the environment.